Innovative design · Lean management · Zhuomei quality · Customer satisfaction

Engineering design

Part Design and Design for Manufacturing (DFM)

The company has been committed to the research, development and production of precision magnesium alloy automotive and industrial parts, and especially has technical advantages beyond other companies in the field of new energy automotive parts and automotive lightweight. Years of research and development, and skill accumulation formed a series of our unique core technology.

Xingyuan provides customers with one-stop services from design, mold manufacturing, die-casting and finishing production, surface treatment and assembly. At this stage, except for surface treatment which needs to be done at our partner suppliers, all other processes are done in our own factory which has a very obvious delivery advantage both in the project development and mass production stages.

Xingyuan provides customers with one-stop services from design, mold manufacturing, die-casting and finishing production, surface treatment and assembly. At this stage, except for surface treatment which needs to be done at our partner suppliers, all other processes are done in our own factory which has a very obvious delivery advantage both in the project development and mass production stages.

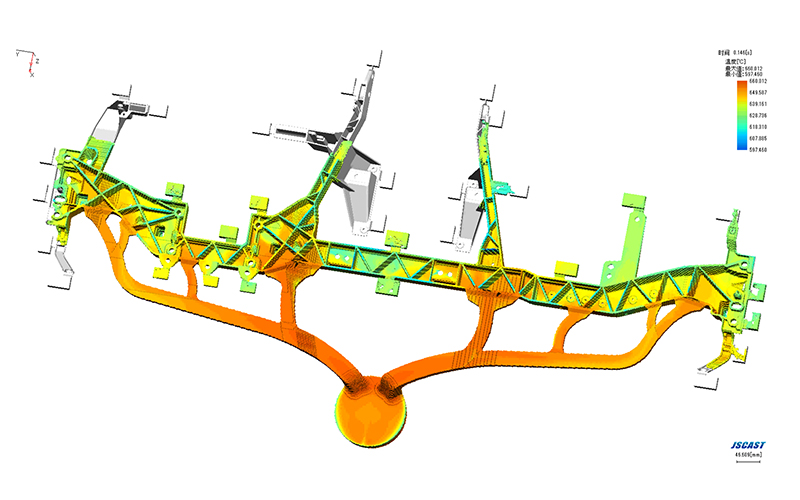

Mold Design and Mold Flow Analysis

Use the first-class casting simulation software JS Cast to design runners, gates and exhaust. This excellent simulation design software is combined with our technology and uses UG 3D software to support the design of die-casting molds. We have successfully developed large-scale die-casting molds from many customers such as Volkswagen, Tesla, and Porsche.